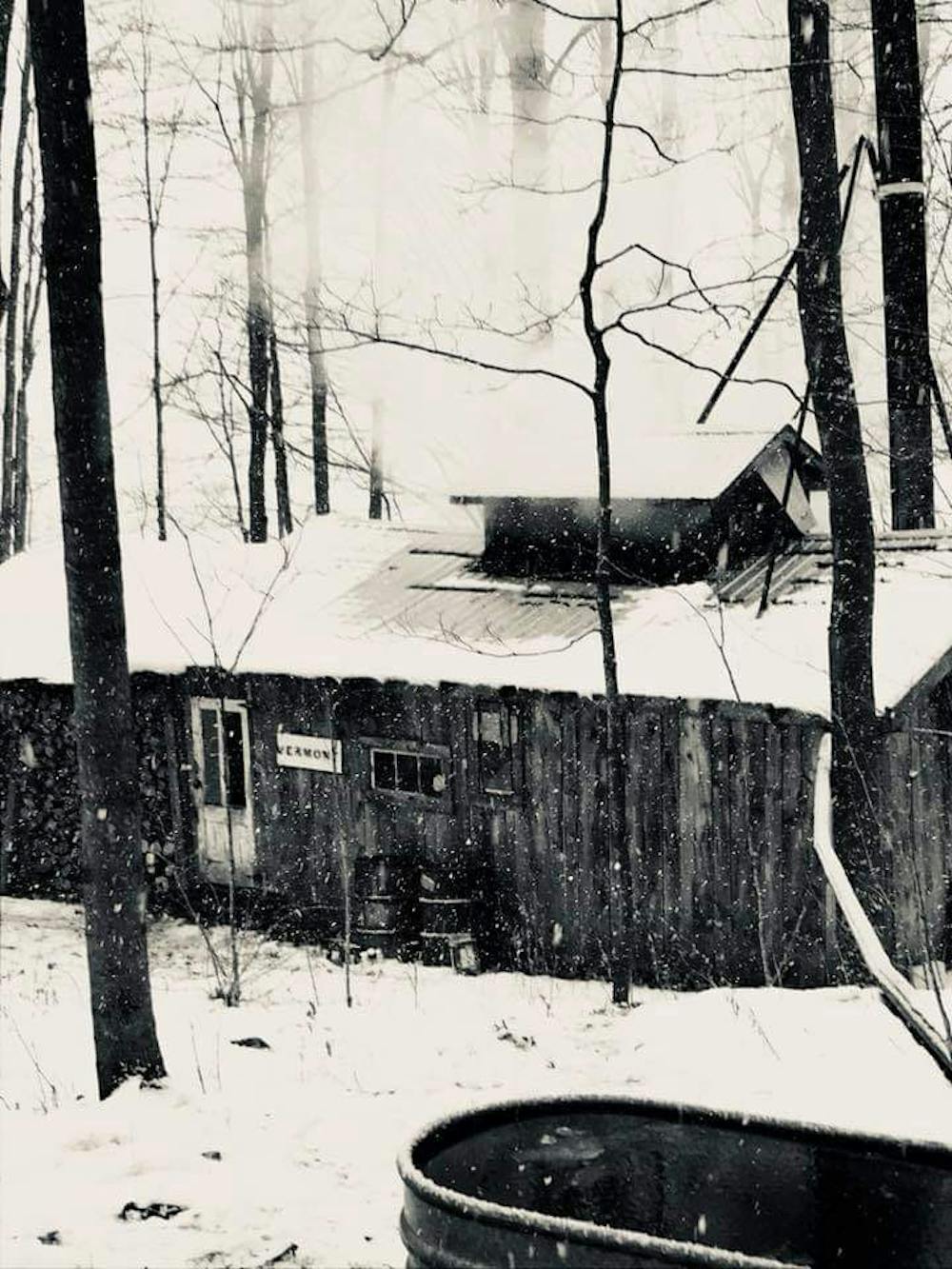

The month of April marks the end of a standard sugarmaking season in Vermont — the weeks when Vermont’s maple syrup producers tap their trees, collect sap and process it for syrup.

The season typically lasts from the end of February until the beginning of April. This year’s sugaring season was similarly warm to last year’s season but had a less extreme temperature range, according to Tim Hescock, a co-owner of the Trade Winds Farm in Shoreham with his wife, Lorraine Hescock.

“This year, I’d say we had a colder winter than within the last few years,” Hescock said.

For optimal sugaring conditions, the ground under the maple trees must freeze at night and thaw during the day. This year’s season was somewhere between a few days and a week shorter than is typical because cold temperatures delayed the start of the season. But this season was also warmer than in years past, with many nights not reaching freezing. Hescock said that while seasons have gradually been warming during his years of sugarmaking, it was different for his older siblings and parents.

“When I was a kid it was still kind of like this — we had years where it was really warm. But I do think about before that, like for my older siblings or my parents, there definitely were harder winters,” Hescock said. These warmer seasons, as well as more extreme fluctuations in temperature throughout the season, seem to be related to climate change.

Ben Seeley, whose parents and grandfather founded Sugar Seeley Works in Middlebury, is also part of a long sugarmaking tradition. Seeley said that sugaring has been affected by changing weather in recent decades.

“Ten years ago, it would start to warm up and then we would have good sugaring weather for maybe a month, if we were lucky. Once it warmed up to about 60 degrees at night, sugaring would be done in April,” Seeley said. “In the last few years, it’s been extremely cold in February, then it will warm, and stay that way for a few weeks. This year, we had a three or four week season, and the weather fluctuated a lot.”

Seeley also discussed the sugaring process, adding that the size of a maple tree should approximately equal the size of the bucket with which it will be tapped. Some trees are so big that they can be tapped with three or four buckets. Two big maples, each about 200 years old, used to be tapped with seven buckets each by the Seeleys, he said. These trees are dying now, but over the years they have spread seeds and some big new trees are now growing nearby.

Seeley said he believes that a number of bigger maple trees have died because of property developments or runoff from salt on roads throughout the last few decades.

As the weather has changed, limiting the window for and ease of sugaring, technological advancements have allowed some sugarmakers to still produce the same amount of syrup as before, if not exceed it.

For Hescock, a vacuuming system has improved the efficiency of drawing syrup from trees, allowing them to tap more trees and expand their business, despite changes to the sugaring season.

“The vacuum system helps draw more sap out of each tree, especially when there’s not a good flow, due to the temperatures not reaching freezing the night before. When it freezes, there’s an internal pressure in the trees and the syrup gushes out,” Hescock said. The vacuum system either intensifies that pressure or creates it, he added.

Modern osmosis technology has also helped with sugaring. Reverse osmosis accelerates syrup production by removing water from sap before it’s put in a syrup evaporator. Vacuums and osmosis generally go hand in hand for sugaring, as increased production of sugaring caused by vacuuming makes reverse osmosis more useful. While this newer technology is becoming more common, it’s far from universal.

Some sugarmakers rely exclusively on traditional methods, which in turn means they are less insulated from shifts in the sugaring season that might reduce syrup quantities. Warren Chase is a third generation sugarmaker at Cota Brothers Maple Syrup in Monkton, Vt. Cota Brothers Maple Syrup does traditional sugaring, meaning they don’t use vacuums or reverse osmosis, Chase explained.

“We just have gravity and buckets,” Chase said. After two years of bad crops, though, Chase said they are considering purchasing vacuums.

“We don’t necessarily make money from sugaring, it’s more for fun, but we’d like to make a little more money from it, so we’re thinking of getting vacuums,” he said.

In addition to sugaring, Chase and his family members work a variety of professions as carpenters, beef herders and hay sellers.

Chase said sugaring is a springtime hobby for his family, something that is relatively common in Vermont. “Whenever you start sugaring, your family does it, it gets in your blood, you’re a sugarmaker. You’re always going to tend to do it, or if you aren’t doing it, you’re going to be helping someone else do it,” he said.

Indeed, many sugarmakers throughout Vermont are part of families that have been sugaring on a small scale for multiple generations. In addition to sugaring, many work as loggers and excavators, like those at Seeley Sugarworks, sell Christmas trees, roping, and wreaths, or grow peach trees in the summer, such as the Trade Winds sugarers.

When asked what his favorite and least favorite part of sugaring were, Seeley had a simple answer.

“I love doing it, I don’t hate any part of it,” he said. This attitude, combined with the hard work of sugarers, has kept the sugaring tradition alive and well in Vermont. As technology advances and seasons change, sugarers continue to make Vermont’s delicious maple syrup.

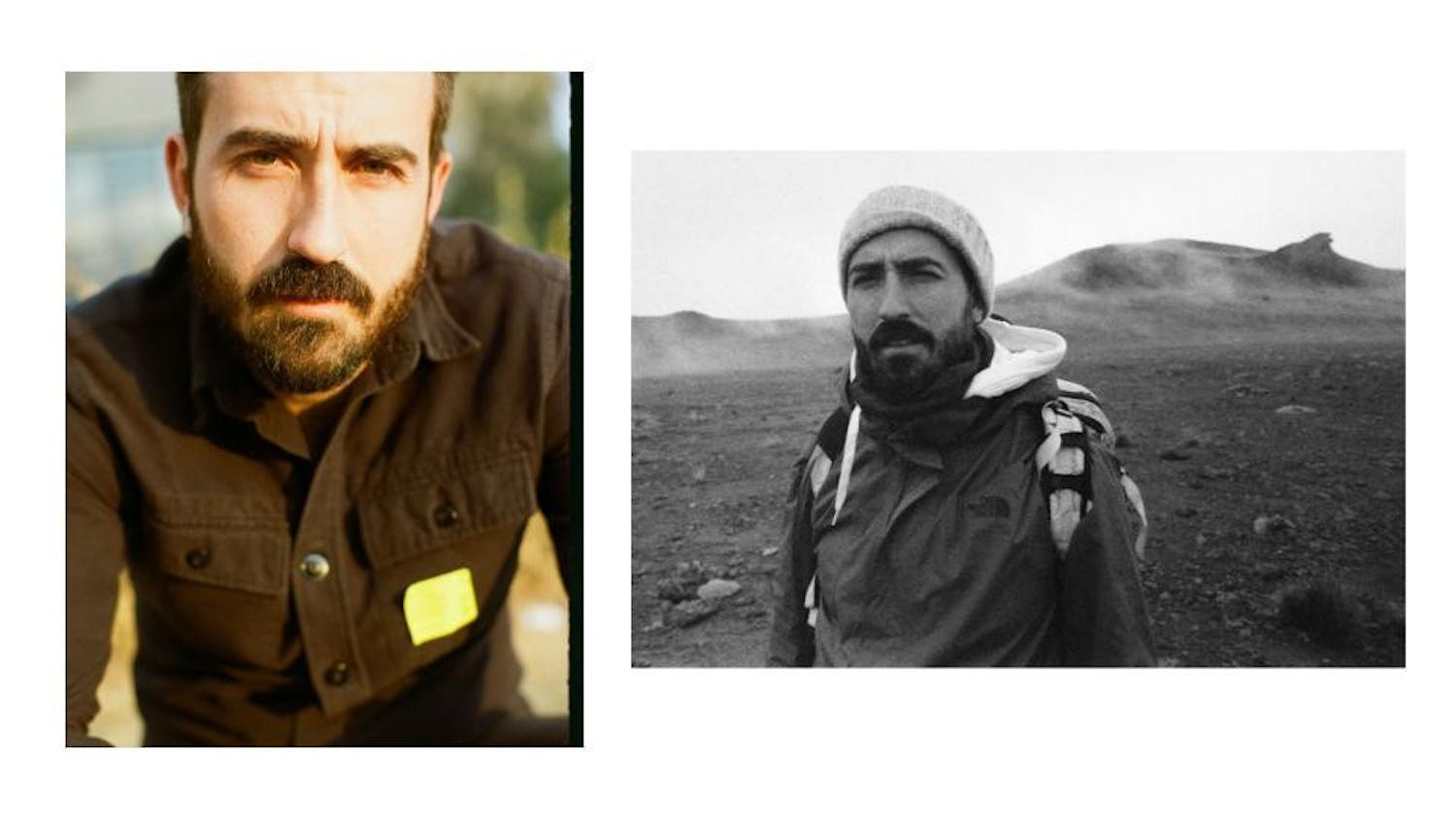

Julia Pepper '24 (she/her) is the Senior Local Editor.

She previously served as a Local Editor. She is a Psychology major and French minor. This past spring she studied in Paris. She spent the summer interning at home in New York City, putting her journalistic cold calling skills to use at her internship doing outreach with senior citizens. In her free time she enjoys reading and petting cats.